RhinoCAM 2023 Expert

RhinoCAM versión Expert (fresado de 4 ejes). Esta configuración permite la creación de operaciones de desbaste y acabado de 4º Eje indexado y continuo. El mecanizado continuo basado en curvas, como el revestimiento de 4 ejes, embolsado, perfilado y grabado, así como el mecanizado basado en superficies / sólidos / mallas, como el desbaste, acabado y mecanizado de proyección de curvas, está disponible. Esta configuración incluye toda la funcionalidad incluida en la configuración de STD.

RhinoCAM Expert (EXP) es la configuración que permite crear operaciones de desbaste y acabado continuas e indexadas en el 4º eje. Mecanizado continuo basado en curvas, como refrentado de 4 ejes, cajera, perfilado y amp; Grabado, así como mecanizado basado en superficies/sólidos/mallas, como desbaste y desbaste. Los métodos de acabado están disponibles.

Esta configuración incluye toda la funcionalidad incluida en la configuración RhinoCAM Estándar (STD).

Características destacadas de RhinoCAM Expert:

- Modelado 2D y 3D, modelado de mallas, modelado avanzado basado en NURBS (necesita Rhino)

- Fresado de 2 1/2 ejes

- Fresado de 3 ejes

- Fresado indexado de 4 ejes

- Fresado continuo de 4 ejes

- Perforación

- Módulo TURN: módulo de programación de torno/torneado de 2 ejes

- Módulo ART – Modelado Artístico (Conversión de Raster a Vector, Imágenes a geometría 3D…)

- Módulo NEST: anidamiento de piezas (anidamiento rectangular y de forma real)

| SKU | MEC-RC-M-EXP23 |

|---|---|

| Código Producto | RC-M-EXP23 |

| EAN | 8435371401606 |

| es_estudiante | No |

| Fabricante | MecSoft |

| Características |

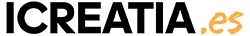

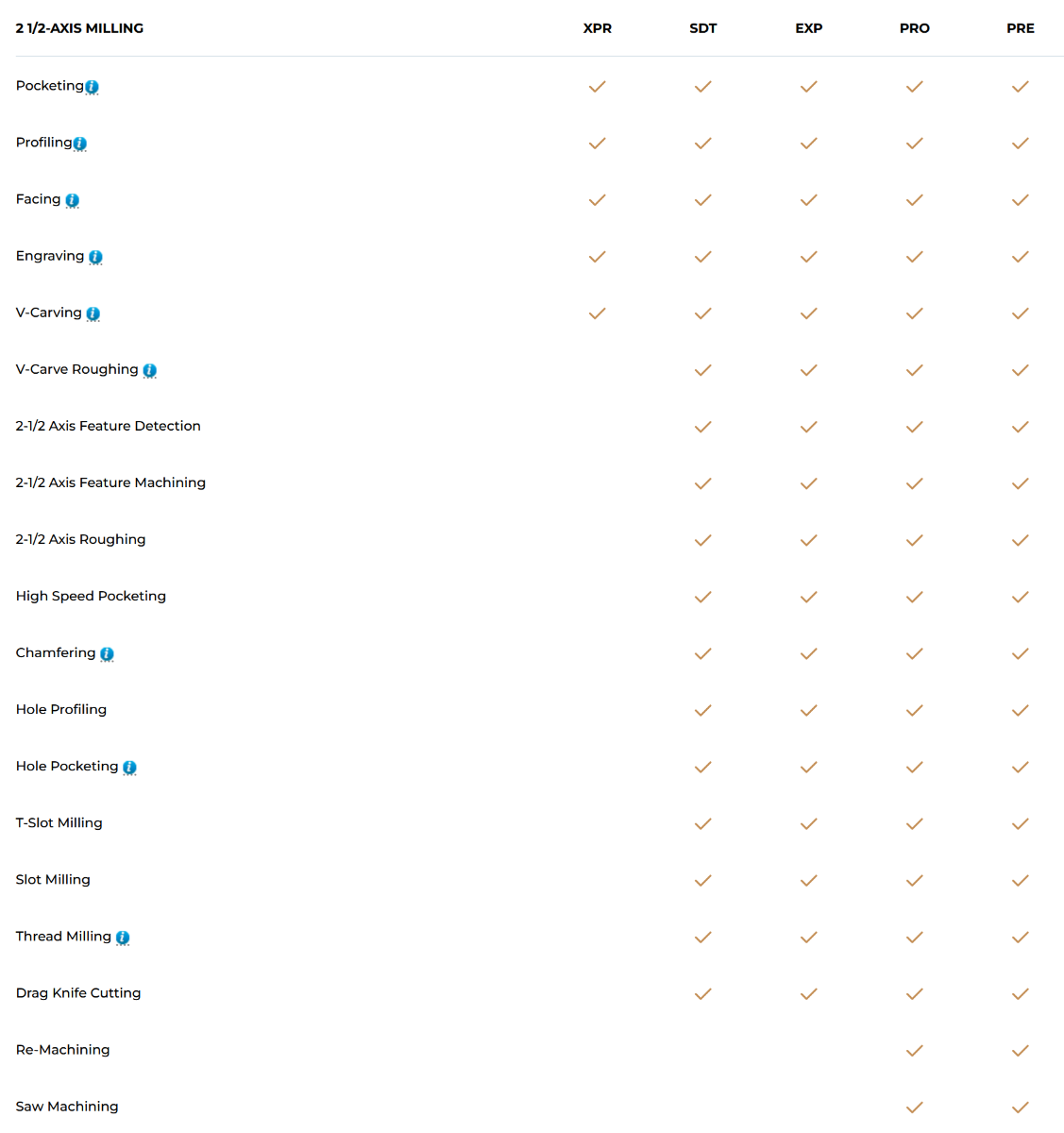

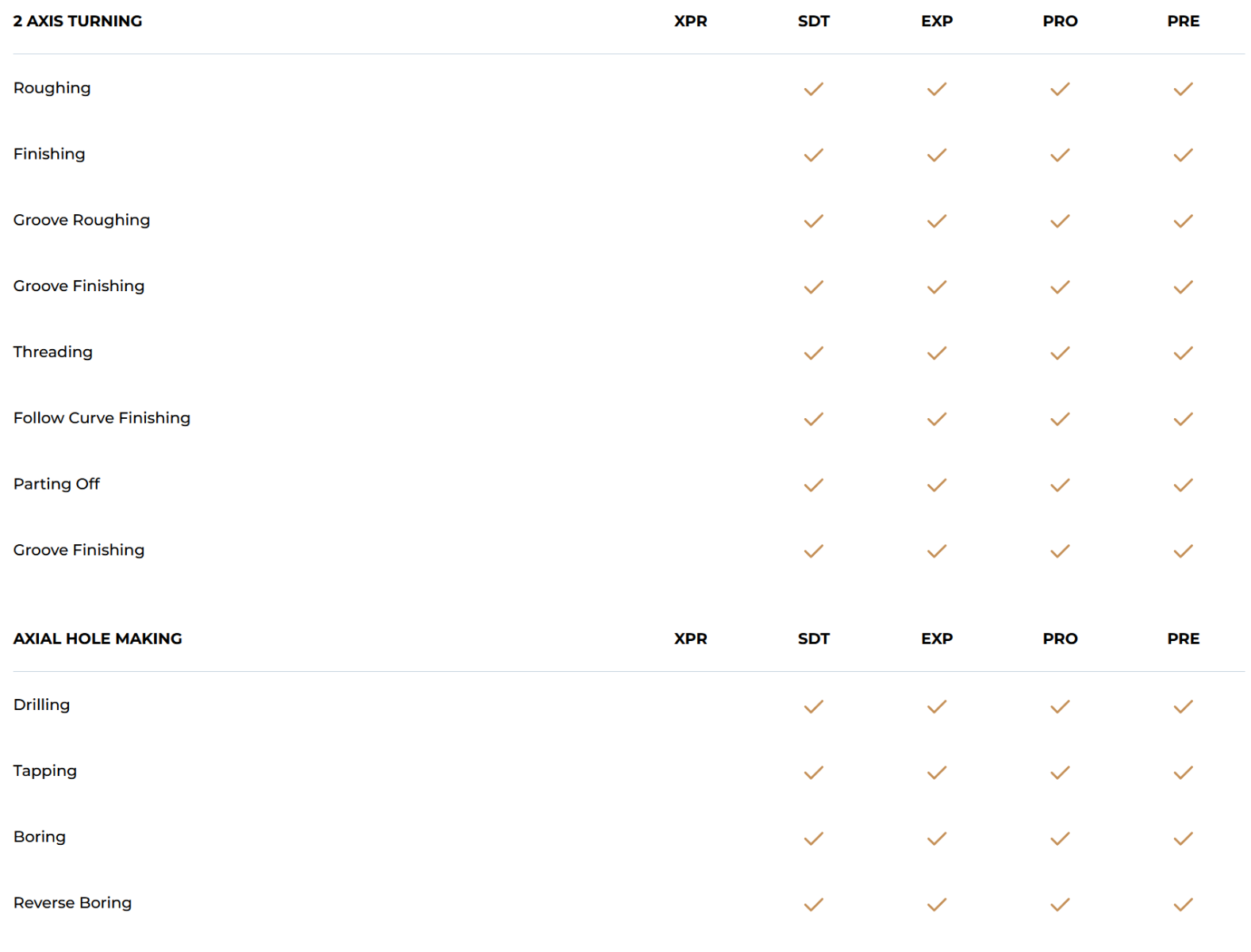

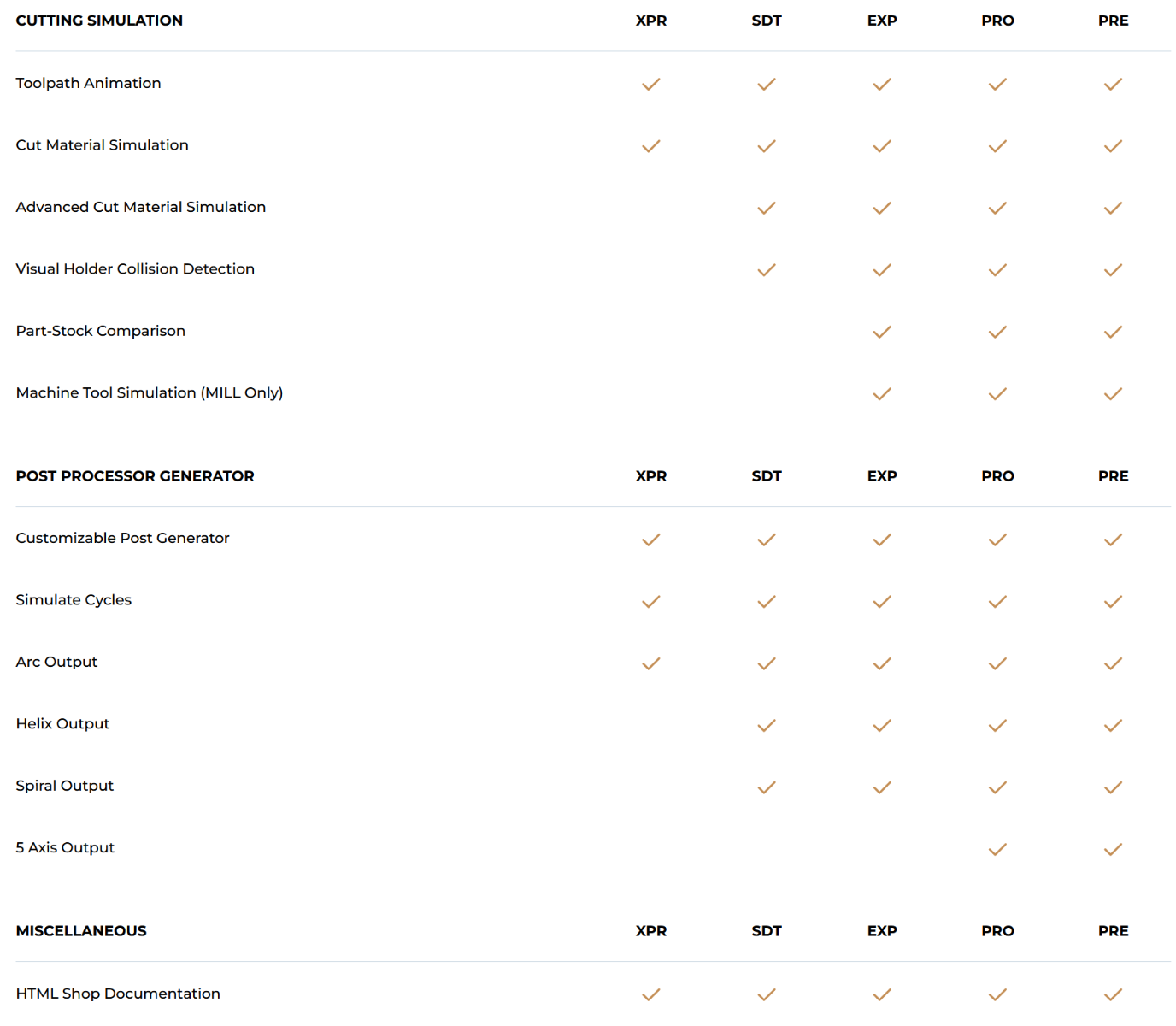

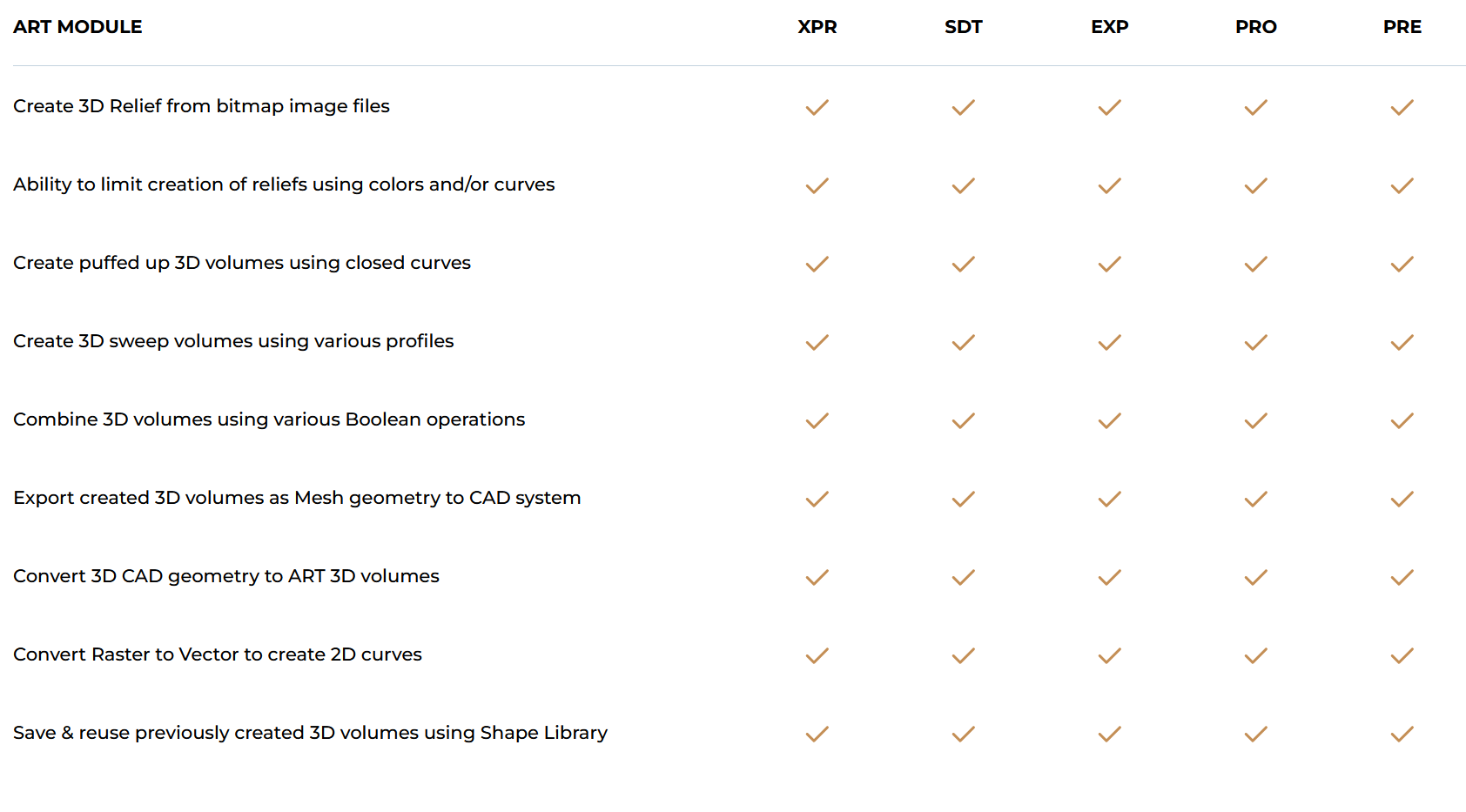

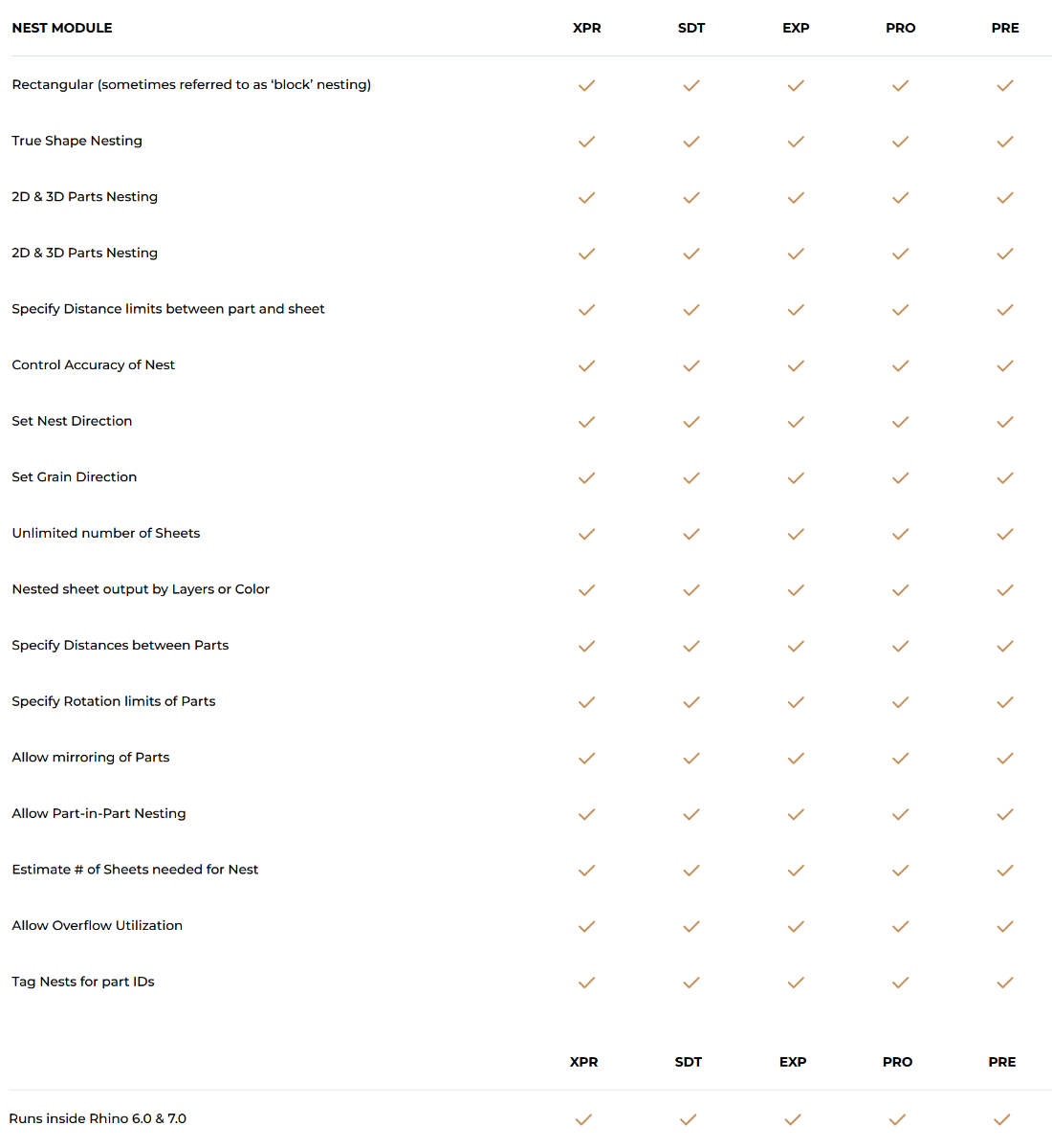

Características destacadas de las distintas versiones de RhinoCAM 2023.

Milling:

Turning:

Common to Mill & Turn:

Artistic modeling:

Parts Nesting:

|

Características destacadas de las distintas versiones de RhinoCAM 2023.

- XPR > Xpress

- SDT > Standard

- EXP > Expert

- PRO > Profesional

- PRE > Premium

Milling:

Turning:

Common to Mill & Turn:

Artistic modeling:

Parts Nesting:

Novedades de RhinoCAM 2023:

RhinoCAM existe en 5 configuraciones distintas, para adaptarse a las variadas necesidades de mecanizado de nuestros clientes.

|

RhinoCAM-TURN: RhinoCAM-TURN es un potente sistema de programación de centro de torneado de 2 ejes que es uno de los cinco módulos que se ofrecen en el paquete de software RhinoCAM. Este módulo incluye desbaste de torneado, acabado, desbaste de ranuras, roscado, división, mecanizado de orificios y posprocesadores gratuitos. El software RhinoCAM-TURN CAM para sus tornos y centros de torneado ofrece un valor excepcional para su inversión. |

|

RhinoCAM-ART: RhinoART or RhinoCAM-ART es un módulo dentro de RhinoCAM que se utiliza para convertir ilustraciones, en geometría adecuada para el mecanizado. Este módulo presenta nuevas y emocionantes técnicas de modelado para modelar formas artísticas utilizando imágenes de mapa de bits rasterizadas. Utilizado junto con las herramientas de modelado 3D de RhinoCAM, ofrece un conjunto complementario de técnicas de modelado para el diseño de joyas, la creación de letreros y la creación de modelos. |

|

RhinoCAM-NEST: RhinoCAM-NEST, un módulo con precio por separado, es la solución rentable de MecSoft para organizar y ajustar de manera óptima formas geométricas en áreas de material en bruto. |

|

RhinoCAM-Mill: RhinoCAM-Mill incluye los módulos de Rhinocam Nest y Art. Un paquete de modelado y fresado diseñado para rotulistas, aficionados, fabricantes y estudiantes. Ideal para iniciarse en la programación CAM. Incluye modelado 2D y 3D, así como métodos de mecanizado de 2 y 3 ejes. Con un precio atractivo para compradores primerizos y empresas con presupuestos limitados. |

|

RhinoCAM MESH: RhinoMESH es un módulo totalmente integrado que se compra por separado y que se ejecuta dentro del modelador Rhinoceros 6/7 NURBS. Este módulo ofrece herramientas eficientes, fáciles y automáticas para limpiar, reducir, refinar y preparar datos de malla 3D para aplicaciones posteriores como el mecanizado NC y la impresión 3D. |

Configuraciones de RhinoCAM:

El software RhinoCAM CAM viene en 5 configuraciones diferentes para adaptarse a las variadas necesidades de mecanizado de nuestros clientes.

|

RhinoCAM Xpress (XPR):Este es un programa de propósito general diseñado para aficionados, creadores y estudiantes. Ideal para iniciarse en la programación CAM. Incluye métodos de mecanizado de 2 y 3 ejes. Repleto de métodos de fabricación lo suficientemente potentes, este paquete fácil de usar no solo es efectivo sino que también tiene un precio atractivo para el comprador consciente del presupuesto o de nivel de entrada. Este módulo incluye el NEST y el ART sin costo. |

|

Este paquete incluye nuestra nueva funcionalidad de mecanizado continuo de 5 ejes. Adecuado para requisitos de mecanizado altamente sofisticados, como la industria aeroespacial, la fabricación de moldes avanzados y la carpintería, este paquete incluye métodos de mecanizado como el mecanizado superficial normal, el mecanizado de virutas y el mecanizado de flujo superficial. El paquete además incluye toda la funcionalidad que se encuentra en la configuración PRO descrita anteriormente. Este módulo incluye el TURN, NEST y ART sin costo. |

|

Este es un programa de mecanizado de propósito general dirigido al maquinista general. Este producto es ideal para los mercados educativos, de pasatiempos y creación rápida de prototipos, donde la facilidad de uso es un requisito primordial. Incluye métodos de mecanizado de 2-1/2 ejes, 3 ejes y taladrado. Este módulo incluye el TURN, NEST y ART sin costo. |

|

Esta configuración permite crear operaciones de desbaste y acabado continuas e indexadas en el 4º eje. Están disponibles el mecanizado continuo basado en curvas, como refrentado de 4 ejes, cajeras, perfilado y grabado, así como el mecanizado basado en superficies/sólidos/mallas, como desbaste, acabado y proyección de curvas. Esta configuración incluye toda la funcionalidad incluida en la configuración STD. Este módulo incluye el TURN, NEST y ART sin costo. |

|

Este potente paquete es ideal para los mercados de moldes, troqueles y herramientas, creación rápida de prototipos para trabajar la madera y mecanizado en general. Este producto se jacta de poderosas estrategias de generación de trayectorias junto con herramientas para controlar eficientemente la herramienta de corte para obtener capacidades de mecanizado detalladas, sin sacrificar la facilidad de uso. Adecuado para usuarios exigentes con requisitos de fabricación sofisticados. La configuración de este producto incluye toda la funcionalidad incluida en la configuración EXP descrita anteriormente. Este módulo incluye el TURN, NEST y ART sin costo. |

RhinoCAM 2023: Introduction to 2½ Machining

Watch this in-depth tutorial video to learn how to setup and machine a 2½ part using Facing, Pocketing and Profiling toolpath strategies. You will also learn how to use pre-defined regions as control geometry.

RhinoCAM 2023: Introduction to 3 Axis Machining

Watch this tutorial to learn how to setup and machine a part using 3 Axis Horizontal Roughing (also referred to a Z-Level Roughing) and 3 Axis Parallel Finishing toolpath strategies.

RhinoCAM 2023: Introduction to 4 Axis Machining

Watch this video to get an introduction to 4 Axis machining with RhinoCAM 2023 from MecSoft Corporation. Indexed machining as well as 4 Axis rotary machining (2 linear+1 rotational axis) is demonstrated and more!

FABRICA lo que tu mente IMAGINA!

Te presentamos nuestro nuevo Webinar Icreatia, en el cual mostraremos el proceso que va desde cómo diseñar los primeros pasos del boceto, hasta cómo llevarlo a la realidad con RhinoCAM.